Helping G-Star RAW put circularity into practice

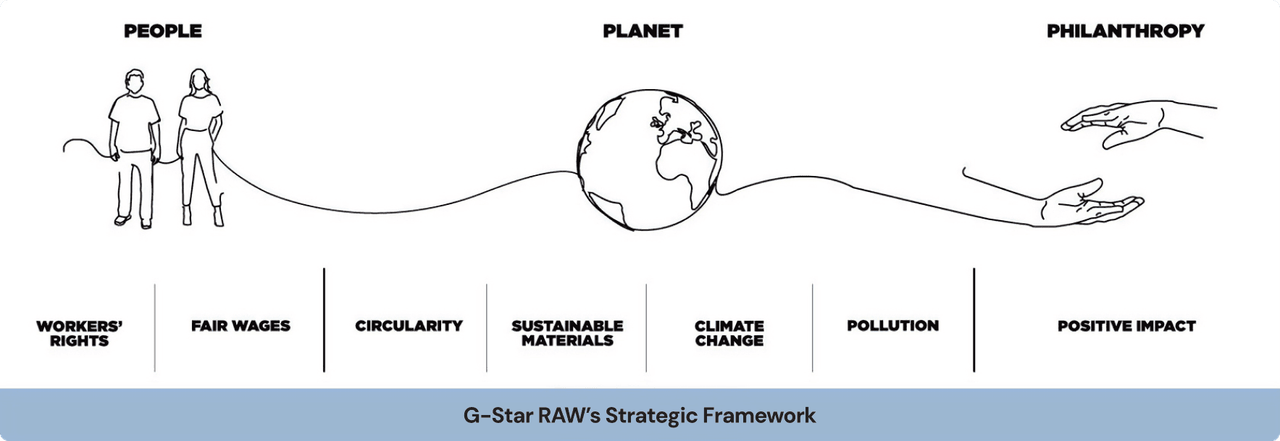

Through hands-on training and pilot testing, G-Star RAW and Circle Economy turned circularity from theory into action—redesigning how denim is made, used, and reused.

Real-world results: What changed at G-Star RAW

Circular design is now embedded in product development through tools, training, and updated workflows.

Teams across departments now share a common language for circularity, beyond just sustainability roles.

Our denim recycling pilot showed that high-value textile-to-textile recycling is technically and financially viable: cutting water use by 9.8%, energy by 4.2%, and CO2 by 3.8%.

A new Rewear collection launched—made entirely from secondary materials.

G-Star scaled initiatives like Return Your Denim and Certified Tailors, supporting resale and repair.

The gap: Ready for circularity but unequipped

The fashion industry produces 100 billion garments every year, most of which end up in landfills or are incinerated. G-Star RAW saw the opportunity to change course, but circular design isn’t straightforward. Trade-offs between quality, cost, and recyclability are complex. Teams lacked shared tools or frameworks to navigate these challenges, and the infrastructure to support circular models—like resale or recycling—wasn’t yet in place.

What we delivered: Ready for circularity but unequipped

Circle Economy worked with G-Star to embed circularity from strategy to execution. We co-led a denim recycling pilot that proved the business and environmental case for high-value recycling. We then delivered targeted masterclasses and tools that helped product teams redesign key denim items with longevity, repairability, and recyclability in mind. What began as a sustainability-led effort became a company-wide shift in mindset, powering product innovation, employee engagement, and the launch of circular initiatives like Rewear.

G-Star’s story shows what happens when research leads to strategy—and strategy leads to action. Want to build your company’s roadmap to circularity?